REMOVAL/INSTALLATION AND

TROUBLESHOOTING FOR AIR

CONDITIONING COMPRESSORS

TROUBLESHOOTING FOR AIR

CONDITIONING COMPRESSORS

: General

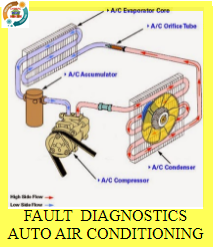

The air conditioning compressor is driven by the vehicle engine .via a ribbed or V-ribbed belt. It compresses and transports the refrigerant in the system. There are different compressor designs available

How they work:

The refrigerant is sucked in as a gas under low pressure and low temperature from the evaporator; it is then compressed and forwarded to the condenser as a gas under high temperature and high pressure.

Effects of failure:

A damaged or failed compressor can manifest itself as follows:

Loss of sealing -

Development of noise -

Insufficient or no cooling performance -

Fault code is stored (automatic air conditioning) -

Development of noise -

Insufficient or no cooling performance -

Fault code is stored (automatic air conditioning) -

Caution!

Before installing a new compressor, you must check the oil quantity and

the viscosity according to the manufacturer's instructions!

There are a number of possible causes of failure:

- Bearing damage caused by a defective tensioner or by wear -

Loss of sealing of the compressor shaft or of the housing -

Mechanical damage to the compressor housing -

Contact (electrical connections) -

Lack of refrigerant oil -

Lack of refrigerant -

Solids (e.g. swarf) -

Loss of sealing of the compressor shaft or of the housing -

Mechanical damage to the compressor housing -

Contact (electrical connections) -

Lack of refrigerant oil -

Lack of refrigerant -

Solids (e.g. swarf) -

- Humidity (corrosion etc.)

Troubleshooting:

Function test and pressure measurement of the system:

- Does the compressor switch on, is the connector plug

securely in place, is there voltage?

- Check that the drive belt is positioned correctly, undamaged,

and that there is tension.

- Check visually for loss of sealing.

- Check that refrigerant tubes are securely in place.

- Compare the pressures on the high and low pressure sides.

- Read out the fault memory.

Attention must always be paid to the following:

The entire air conditioning system must be cleaned to 100 % and the

consumables must be replaced when the compressor is replaced.

The entire air conditioning system must be cleaned to 100 % and the

consumables must be replaced when the compressor is replaced.

kandi younes